As fortune would have it, I had to deliver a rather lovely watch to a client in Portland late December 2014, so I had my excuse to make to trek to central Oregon and visit my friend Keaton. Having initially met him at Baselworld in 2012, and again in January 2014 when he visited Solana Beach to deliver the first two 1 in 30 pieces, I had yearned to visit his place of work. As many of you know, I love to visit watchmaker workshops and see where these amazing folk create their art form. One can glean aspects of their world, that often make more sense when taken in the context of where they work.

Heading into Sisters, OR.

Keaton is doing something extra-ordinary in central Oregon, making his own watches without the benefit of the nearby watchmaking infrastructure, that exists in Switzerland and Saxony, Germany. His schooling and initial training was in Pennsylvania, after which he returned home to his native Oregon to restore watches and pocketwatches, whilst beginning the ideas and design of his first serial production model, the 1 in 30 Series. Starting with the most important part of a watch, the time keeping regulator, the balance wheel, he created his own from scratch. That in and of itself is to my understanding, not an easy thing to do, and takes full comprehension and understanding of the watchmakers art form. So from this starting point, the remainder of the watch came into existence, and this is what prompted me to commit to the first one, even before I met Keaton and saw his prototype in person at Baselworld in 2012. The production watch is slightly different cosmetically on the dial side, and he improved his click system for the main barrel. I preferred 18K RG for the name plate and watch serial number plates over the 18K YG parts of the proto. His balance bridge is reminiscent of a tourbillon bridge from a vintage pocketwatch. Being expertly hand polished, it shows off his freesprung balance wheel with it's 18K adjusting weights.

Keaton’s image of his balance bridge!

An image from Keaton of his own proto piece showing the balance wheel with gold weights.

My balance bridge in my watch.

My watch.

I arrived in Bend, Oregon on Sunday evening after driving through a snow storm and frozen roads. Keaton greeted me with a smile and warmly invited me in to his humble abode. Middle of the main-living room was a cabinet full of horological items ranging from clocks from vintage planes to tools used in watchmaking. I knew I was in for a treat the following day! We dropped my bag and headed out to dinner. Bend has some quite good restaurants I hear and the one Keaton took me to in the downtown area, old town, was excellent. We returned to his home, and proceeded to chat about watches, the business and then got into a couple of amazing books, one about A. Lange & Sohne, which had stunning photos of historical watches going back to the mid 1850's. As a fan of Saxon watchmaking, this was quite a treat! The following morning I awoke to 2 inches of fresh snow. A first for me in over 6 years. There is no snow in San Diego! Lake Tahoe back in 2008 or 2009, was the last time I had been in a snowy environment!

We headed out at around 8.30am to Sisters, about 30mins drive in the snow, where Keaton has his workshop. Unfortunately I was not able to see the majestic mountains of the Cascades that lie to the west of where we were headed. In clear weather, one has a stunning view of Mt. Bachelor and the two Sisters Mountains. Between 9000-10,000feet, these offer quite a view I'm told! Arriving into Sisters, Keaton parked and we went into the clock shop, where he has his workshop. The owners of the clockshop, Ed & Kathi Beacham kindly showed me around, Ed makes clocks from scratch, I'd say he is a rare bird too! Their shop was full of long case clocks as well as many wall clocks adorning almost the entire wall space. We walked over to the Sisters Coffee shop, procured some fresh Earl Grey tea and walked back to start my day of education and observation. Never have I been able to spend a whole day observing a master watchmaker in his element.

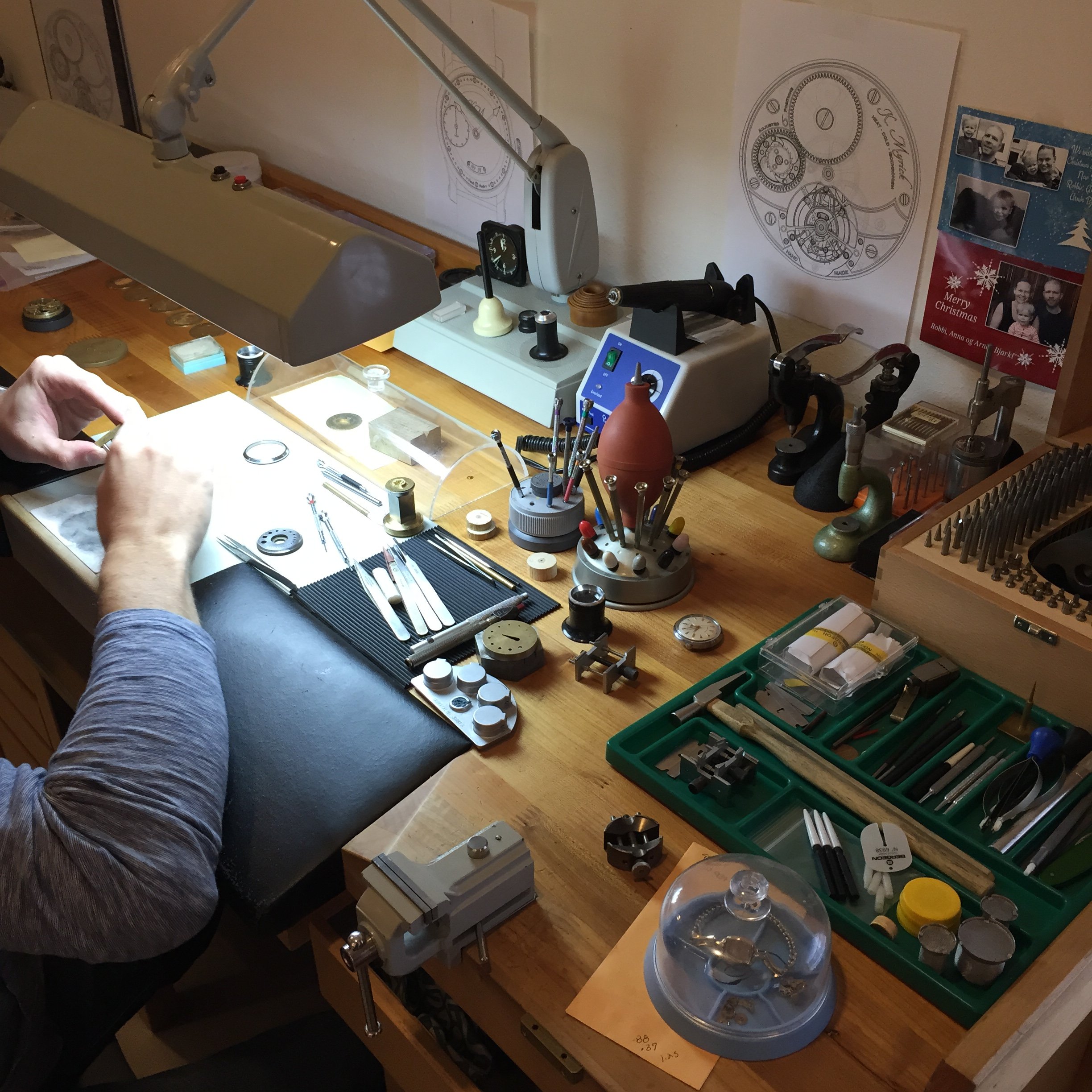

Black polishing a screw

Keaton has his desk with computer, watchmaking bench and various other tables with a variety of tools and machines in a 1/4 of the upstairs gallery of the Beacham Clock company. Downstairs in a separate room off to the back, is the dirty work area, where a large lathe, a couple of basic CNC machines and the ultrasonic cleaning machine reside. Keaton recently gained a colleague, Andrew, another Wostep trained watchmaker to share some of the restoration work and take on more of the servicing of modern watches, while Keaton dedicated more and more of his time to creating his own watches. Andrew's bench is downstairs in the back of the main room, he was restoring a lovely old Glashütte pocketwatch, an Assman, which was a treat to see.

We then headed back upstairs where Keaton explained what each tool was for and when he typically used it in the manufacturing of parts and in some cases for the hand finishing. He also has an optical measuring projector, an immensely useful and important tool for making sure the parts are the correct shape and dimension. The watchmakers go to lathe, the Schaublin 60 was in it's place nearby another lathe, the Boley. These are high precision lathes, one finds in all workshops of watchmakers worth their salt! Keaton has designed and is in the process of making his next watch also. He showed me in the CAD program, the details of this lovely watch. I cannot reveal what it is yet, but it will give him the recognition due his level of watchmaking mastery. It will also give more of an insight into his inspiration from the masters of old, in particular, one fellow responsible for some very famous watches of extremely high chronometry and beautiful execution. A CAD print out of the caliber sits front and center on the wall above his bench. Over the course of a couple of hours, which by the way flew by, only to be reminded of the passage of time by the cacophony of chiming clocks every hour, quarter and half hour, that occur in a clock shop. Keaton is used to it, I on the other hand almost jumped when the top of the hour was reached! I didn't count all the clocks, but I think a conservative estimate, is 100, with at least 20 of them being tall case chiming grandfather type clocks! Keaton showed me how he blues his hands and screws by heat. A controlled electric heater provides a more consistent heat source than the traditional paraffin lamp. It is still a highly skilled procedure and takes many hours of practice to get the desired shade of blue correct. Too long and the piece has to be polished again, cleaned with very strong nasty chemicals, prior to heat blueing.

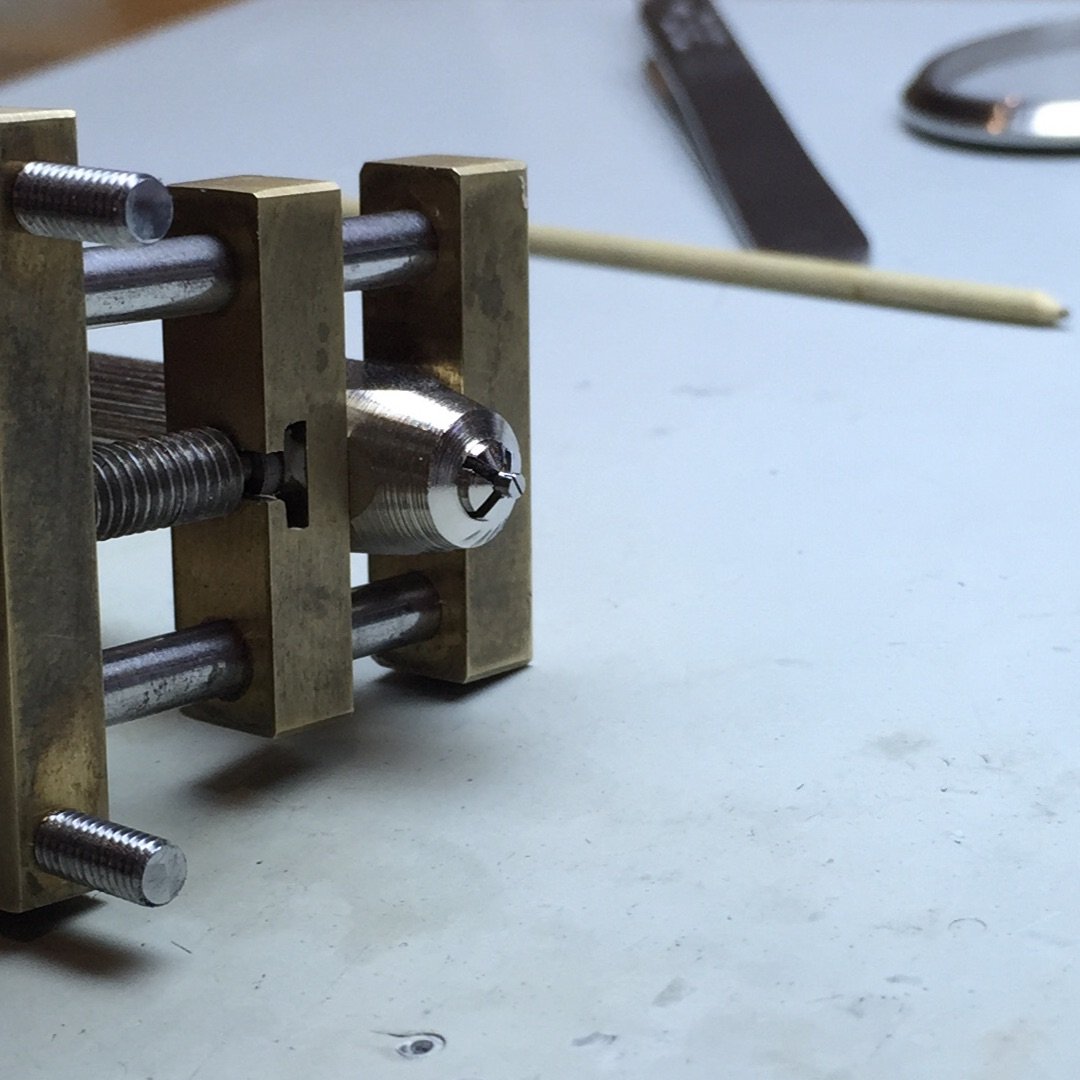

The jig for flat polishing screws

Here’s the screw within!

He showed me his jigs for flat polishing screws, which is done with a very fine diamond paste and a flat ceramic plate. I had an opportunity to try my hand at this time consuming exercise, being as careful as possible, I still managed to tip the jig and cause one side of the screw to have a slight bevel. It was no longer flat polished!!! So began the work to flatten it perfectly, which one can see in reflected light. Talk about labor intensive work for a small little screw. Knowing how many screws are in a basic watch, one quickly comes to appreciate what it takes to make a hand finished watch. As much as I sometimes think how I might well have enjoyed being a watchmaker, the reality of working with such small things on a daily basis might be more a romantic idea than the reality I experienced polishing a screw on Keaton's bench!

He revealed the four calibers he is currently working on for the watches he has sold, they were in varying stages of completion. Months away would be my educated guess. Of course these watches will be finished to his high level and those lucky four clients will get to enjoy the fruits of his labor, in beautiful piece of micro-mechanical artistry that Keaton will have poured his heart and soul into. This is one of the main attractions for me when working with an Independent Watchmaker and to me the most compelling aspect of the process, getting to see the final watch being created over time, knowing the watchmaker toiled over this for weeks, months and even years, in order to produce a timekeeping object that one can wear and enjoy on a daily basis.

We then popped across the road for lunch, which gave me a break from tiny watch parts. Again a reminder of why I'm happy to let the experts like Keaton and his ilk, do the work, whilst I get appreciate it!

One of the factors that allows for a slightly easier ability to construct his own watches in Sisters, is the amazing proximity to one of the two CNC wire erosion/cutting machines in Oregon, operated by individuals that do custom work for a variety of clients. Of all the places, the Sisters airport, has a fellow working away in a small workshop, creating amazingly high precision metal objects, mostly for the medical industry he revealed. Keaton befriended him, and now has a way to get several of his tiny parts produced about a mile from his workshop. It is also the facility that will allow for him to finally make his own cases. This is a huge benefit for him and I'm excited to see my watch returned to Oregon in due course to be retro-fitted with his own case. Currently it resides in an off the shelf Fricker case, sourced out of Germany.

We spent 20 minutes or so chatting with Keaton's friend, I showed him my watch and a lovely Speake-Marin I was considering buying. His appreciation was exciting to see. We then headed back to the workshop, to finish up the day prior to joining Keaton's parents for dinner. Back at his home, I was given a little insight into another of his loves, music. In fact at one point earlier on prior to his choice of the watchmaking path, he was seriously considering the career of a session musician. Plugging in his electric guitar, he showed me some of his obvious talent, and as a lover of live music, I was enthralled.

Had he not decided to be a watchmaker, this was his alternate professional option!

The following day, we enjoyed a very good breakfast, discussed more aspects of our mutual business needs and wants, then headed out to the Metolius River to see the stunning scenery and one of the places Keaton goes to recharge his creative batteries. I can see why it works for him to be here in central Oregon. It is an absolutely lovely part of the world with a very good fly fishing river, that allows for this man to create his watches.

Metolius river.

What a fabulous trip and a big thank you to Keaton for hosting me and showing me this little slice of horological heaven in central Oregon.